It is a common process inwood productionmills and effectively reduces the moisture content of green timber to “workable” ranges, which prevents the variety of issues that can result from excessive moisture levels in wood.Kiln schedules are used to determine the temperature and relative humidity needed in the kiln to dry specific wood products at a satisfactory rate without causing objectionable drying defects. A typical kiln schedule is a series of temperatures and relative humidity, which are applied at various ···

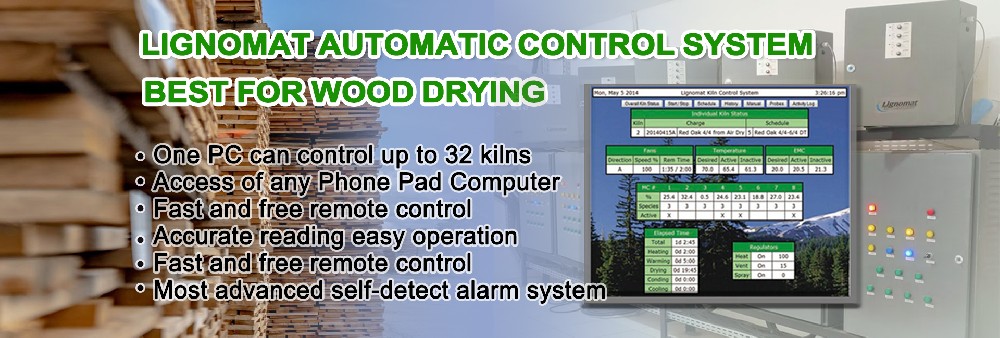

Timber dry management controls offer flexibility and ease of use. When using a timber dry kiln management system, operators have a straightforward, simple to use, flexible program. Kiln operators can make instant changes on screen interfaces. This is feature customers should look for when selecting the ideal dry kiln system for their lumber. This drying control technology uses a proven and cost-saving methodology driven by results.The Lignomat control system stores drying schedules for hundreds of wood species from···

In manufacturing there are growing concerns about the environmental costs associated with running large scale timber operations. Timber dry kilns offer a uniquely sustainable alternative with the wood waste boiler option.Essentially, the wood waste burner runs on wood chips and other wood waste created in the milling process. This process can then be used to provide power to your industrial drying unit – replacing other costly and non-sustainable methods. In addition to this creating an efficient power source, it ···

1.1 Basic structure of wood drying kilnThe wood drying kiln is composed of aluminum alloy metal shell, ventilation system, heating system, spraying system, moisture venting system and automatic control system. The control method of wood drying kiln - realize fully automatic control of drying with the computer.1.2 Working principleLoading the wood stacks into the drying kiln according to the method of sawn wood storage. The radiators heat up the air inside the kiln, and the fans circulate the hot air through the rad···

Product Categories

new products

Copyright © 2024 Harbin Hildebrand Machinery CO.,ltd. All Rights Reserved. sitemap-xml sitemap-txt